SAP MM basics for beginners

SAP beginner may have to consider the basics of the SAP MM and complete information about what and how it is made use of in any organisation. The need for materials management (MM) was first required in manufacturing undertakings.

SAP MM is the short form for Materials management; it is a part of the logistics area which helps to manage the procurement activities, invoice verification and material planning. It deals with managing the materials of an organisation with the aim of reducing costs and increasing productivity and at the same time is flexible to accommodate changes. MM is basically used for Inventory management and procurement. The cost of material is kept under check. Sometimes the cost of indirect materials also increases the total cost of production. Hence, there is no proper control over such materials.

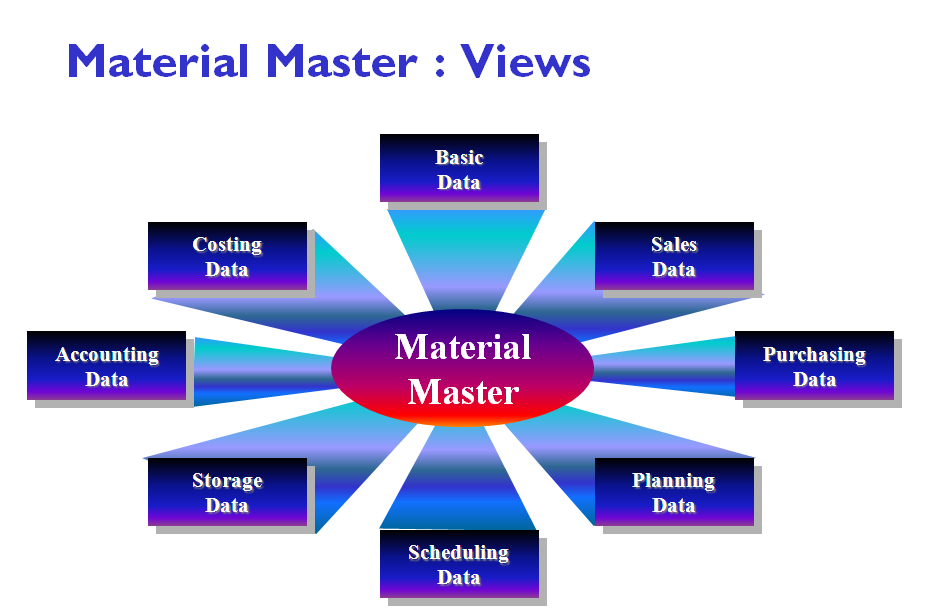

The MM module contains basic master data: vendors, Materials, purchasing data and customer master records for foreign trade.

The procurement cycle consists of the following phases:

Source determination: The purchasing material helps you identify the potential sources of supply based on existing long term business agreement and on past orders.

Determination of requirements: Materials requirements are either identified via materials planning and control or through user departments. You can enter purchase requisitions by yourself, or it can be generated automatically by the control system and materials planning.

Purchase order processing: The Purchasing system carries information from the requisition which helps you create a purchase order and quotation. Vendor scheduling contracts and agreements are also supported.

Vendor Selection and Comparison of Quotations: This system is capable of imitating pricing scenarios, allowing you to compare a number of different quotations and on selecting the proper and required quotation. Rejection letters are sent automatically.

Goods receiving and inventory management: initially, goods received and sent can confirm the receipt of goods by simply entering the PO number.

Purchase order follows up: it checks the reminder period you have specified and generates automatic reminders if necessary at pre-defined intervals. It also provides an update status of quotation, purchase orders and purchase requisition.

Invoice Verification: it supports the checking and matching of invoices. Since the system has access to goods receipt data and PO number it speeds up the process of clearing and auditing invoices for payment.

Inventory control or management: Inventory basically refers to the materials available in stock. It is also known the idle resource of an enterprise. It represents those items, which are either in the process of manufacturing or they are stocked for sale, they are in the form of materials, which are not utilised yet.

SAP Materials management covers all tasks within the supply chain, including vendor evaluation, consumption based planning and invoice verification. It also includes warehouse management to manage stock until the cycle begins again.

interests among the learners about the SAP MM and improvises your scope in SAP career; it helps you create a prospectus which leads you to define your success. It provides you with the appropriate materials so that you can easily manage to cover and grow your knowledge about the topics.